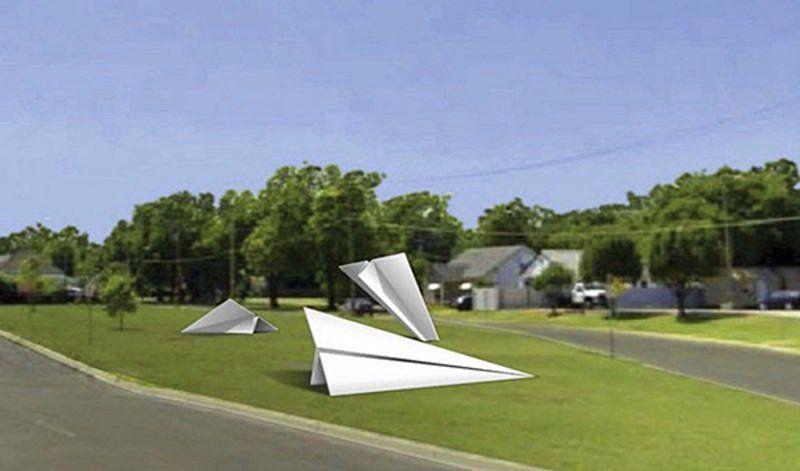

Public Art Commission of Enid is continuing to discuss a citywide project to adorn Enid with 5-foot by 12-foot paper airplanes, made from fiberglass.

Oklahoma City has bison, Tulsa has penguins, Stillwater has butterflies, but paper airplanes capture the spirit of what Enid is, and wants to be, like nothing else the commission could think of.

A makeshift toy and childhood staple, the paper airplane is playful by design, and the sized-up fiberglass models will send a message that Enid is the ideal place to raise a family, PACE member Michael Shuck said.

At the same time, it acknowledges Vance Air Force Base and the abundant wind harnessed by industry.

“It also represents that we’re kind of this family that raises pilots out here,” Shuck said. “They come in as kids and then they leave and take over the sky.”

“Lift,” as the project is called, is Shuck’s brainchild. He had humbler intentions at the start, had a single specific site in mind to install the paper planes, but the commission suggested it could be expanded to include businesses, parks and green spaces in all corners of Enid.

If the support is there, no part of the community would be left out.

The plan, currently, is to start small, putting up a plane or two at Enid Woodring Regional Airport, letting the community see for itself what this endeavor looks like.

Hopefully, businesses and others see the potential, decide to take part, buy a paper plane for their property and have it decorated how they see fit.

“The idea is to put them in unique places, around the corner, on top of a building … to where you just kind of turn around and, ‘Oh, there’s one,” Shuck said.

While the planes will be the same size and shape, they can be anchored in different positions, be aimed in various directions, and each sponsor can decide how to decorate their plain exteriors.

Marcy Jarrett, Visit Enid director and PACE member, said if “Lift” is a success, it will help showcase Enid’s unique identity to visitors.

“It’s not necessarily an overall theme, but it really speaks to the DNA of the community. It’s really to your heritage, to your culture,” Jarrett said. “It will be very fun to see this project take off. To see where it goes … where (the planes) will be placed, how they will be placed, how they will be used, how they will be decorated.”

According to Shuck, it will be at least six months before the company capable of producing the fiberglass planes will be able to do so.

Each plane will cost around $2,000 to $3,000, though an initial purchase will be pricier due to the uniqueness of the design requested, Shuck said. The company will have to put together a special “mold” to make the planes.

Story provided by Enid News & Eagle

Written by: Mitchell Willetts